Fabricated Material

Hi-Tech Engineers is a pioneer in customized metal fabrication solutions, serving industries across India for over two decades. Our capabilities include cutting, bending, punching, welding, and assembly—executed with precision using state-of-the-art equipment and expert manpower. From small custom parts to large industrial assemblies, we fabricate components to exact specifications, ensuring performance, reliability, and cost efficiency.

We specialize in Mild Steel, Stainless Steel, and Alloy Steel fabrication—providing tailored solutions for industries such as Power, Cement, Oil & Gas, Fertilizers, Infrastructure, Refining, and more.

Our Key Fabrication Services Include

- Laser Cutting

- CNC Bending

- Hydraulic & Power Pressing

- MIG & ARC Welding

- Plate Rolling

- Punching & Drilling

- Pipe Cutting & Bending

- Custom Assembly & Sub-assembly Integration

Fabrication is carried out at our fully-equipped facility in Mandi Gobindgarh (4000 sq. ft.), supported by our corporate office and support unit in Bathinda (2000 sq. ft.). All fabrication activities are backed by our dedicated quality control team, ensuring adherence to industry standards.

Steel Structures

A steel structure is a metal structure which is made of structural steel components connected to each other to carry loads and provide rigidity. Because of the high strength of steel, these structures are reliable and require less raw material than some other types of structure such as concrete. In modern construction, steel structures are used for almost every type of structure including heavy industrial building, high-rise building, equipment support systems, infrastructure, bridges, towers, heavy industrial plant, etc. Depending upon the application, a structure can be painted, hot dip galvanized or powder coated. Following are the Main structural types:

Types of Structures Fabricated:

- Frame Structures (Beams & Columns)

- Truss Structures (CHS, SHS, I-Beam)

- Grid & Arch Structures

- Pre-stressed and Modular Frames

- Equipment Support & Load Platforms

- Tower, Bridge, and Plant Structures

Finish Options: Painted / Hot Dip Galvanized / Powder Coated

Usage: Buildings, Plants, Sheds, Equipment Mountings, Bridges, etc.

Quality Assurance: Lab-tested raw material, dimensionally verified, and structurally certified

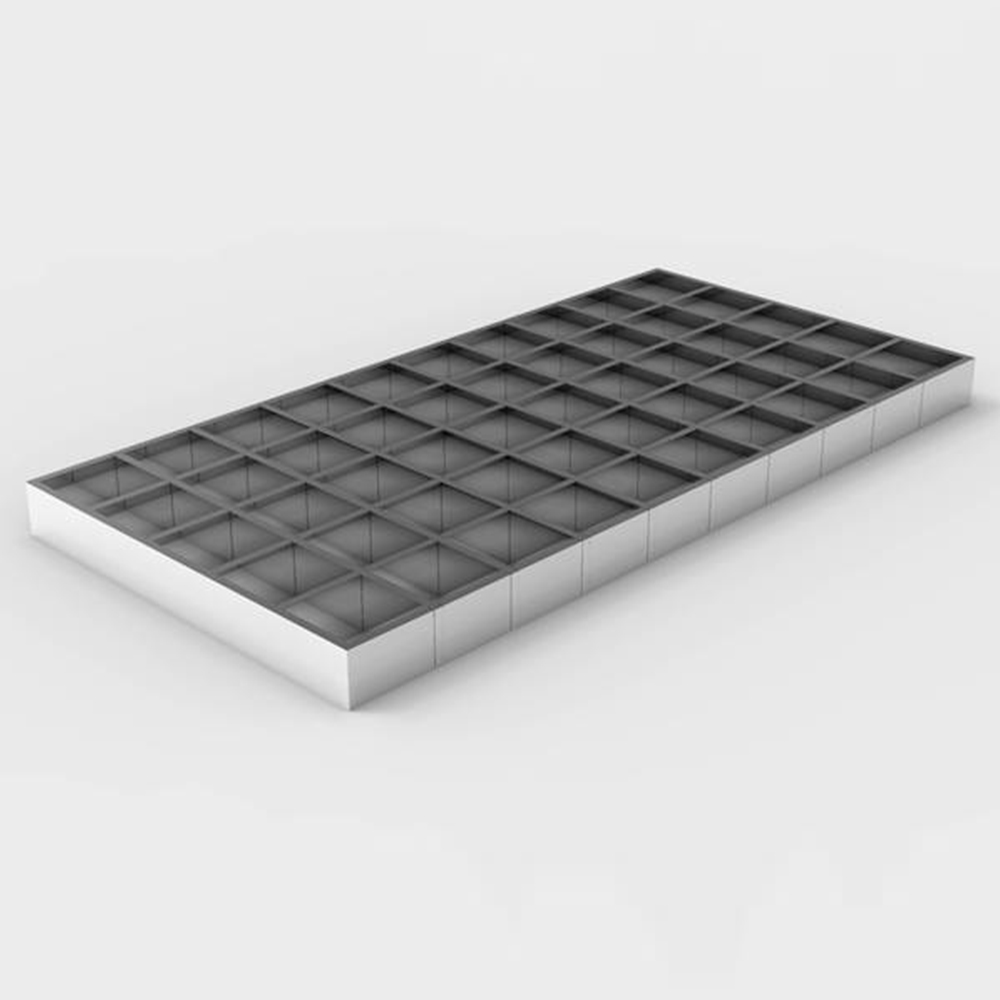

Gratings & Grills

Steel Bar Grating is an open grid assembly of metal bars, in which the bearing bars, running in one direction, are spaced by rigid attachment to cross bars running perpendicular to them or by bent connecting bars extending between them. The great strength and load-bearing capability of mild steel grating is one of its key features. The mild steel composition provides good structural integrity, allowing the grating to withstand severe loads with little bending or distortion. This makes it suitable for walkways, platforms, stair treads, ramps and industrial flooring in a variety of industries such as manufacturing, construction, oil & gas, and transportation.

At Hi-Tech Engineers, we use prime quality raw material along with best industry practices in order to fabricate gratings of the highest quality. Our gratings are optimally designed, dimensionally accurate and thoroughly welded which can sustain higher loads and can impart longer life to the structure. As per the usage of our client, we are supplying gratings in self finish, painted or hot dip galvanized.

Features:

- High load-bearing capacity

- Accurate welding for extended durability

- Supplied in Self-finish, Painted, or Hot Dip Galvanized

- Customizable sizes and shapes based on client drawings

Used In: Power plants, Petrochemicals, Refineries, Manufacturing, Transport Terminals

Handrails

A handrail is a rail that is designed to be grasped by the hand so as to provide safety or support. Handrails are commonly used while ascending or descending stairways and escalators in order to prevent injurious falls, and to provide bodily support in bathrooms or similar areas. Handrails are typically supported by balusters or attached to walls.

We at Hi-Tech Engineers fabricate a wide array of handrails and walkways which serve their purpose for various industries like power plants, refineries, fertilizer industry, cement plants, etc. We are using highest quality hollow sections for fabrication of rails and through our expertise the fabricated handrails are highly rugged and can withstand high loads. The hand rails can be welded socketed or bolted as per the requirement of customer. As per the usage of our client, we are supplying handrails in Stainless Steel and Mild Steel which can be further painted or hot dip galvanized.

Types:

- Socketed or welded handrails

- Bolted railing systems

- Custom railing for stairs, platforms, and catwalks

Materials: MS, SS304, SS316

Finish Options: Painted, Galvanized, Polished

Industries: Power, Fertilizer, Cement, Infrastructure

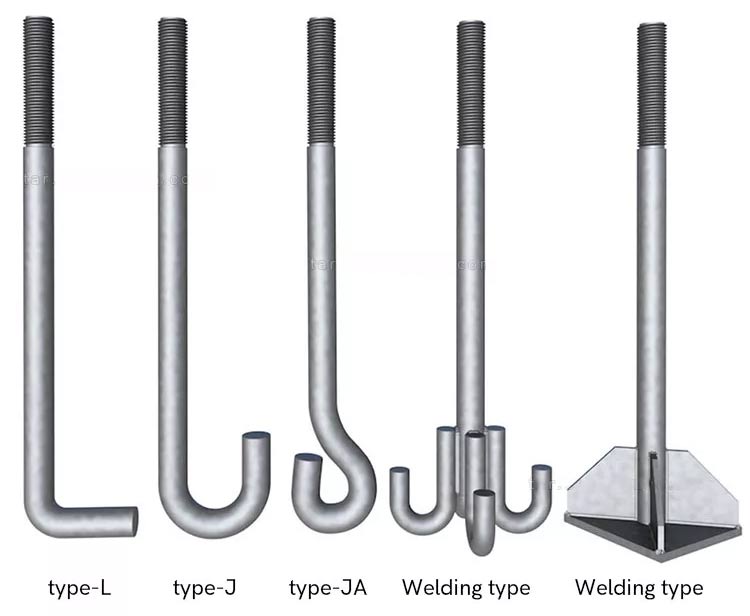

Foundation Bolts

Foundation Bolts are long threaded bolts made out of round bar and are used for anchoring steel structures, machinery, transmission towers, etc. to the concrete or civil foundation. Depending upon the usage, these foundation bolts can be straight, bent (L or J), hooked or plate welded.

We are well equipped with modern machinery in order to fabricate any type of foundation bolts in accordance with the latest industry standards. We use highest quality raw material of round bars which are thoroughly tested for various chemical and mechanical properties so as to withstand high loads, tough weather conditions and any sort of natural calamities. We have monthly capacity of approximately 250 MT and are subsequently upgrading the infrastructure on regular basis. The foundation bolts are made out of Mild Steel, Stainless Steel or Alloy Steel (EN8, EN9, EN24) and are heat treated as per the requirement. As per the usage of our client, foundation bolts can be in self finish, painted or hot dip galvanized. The threads are well greased and wrapped and we take special care for packing the bolts in order to avoid any damage to threads during the transit.

Specifications:

- Materials: MS, SS, EN8, EN9, EN24

- Threading: As per IS/ASTM standards, well-greased & protected

- Capacity: Up to 250 MT/month

- Finish: Self, Painted, or Hot Dip Galvanized

Applications: Machinery installation, steel structures, towers, industrial foundations

Testing: Mechanical, Chemical & Hardness Test Certificates available on request

Tree Guards

Our MS Tree Guards are designed to protect saplings in outdoor and urban environments.

Features:

- Strong, durable MS construction

- Portable, Interlocking or Fixed Frame designs

- Reflective tapes for visibility

- Branding & signage options available

Materials: MS, GI, SS (on request)

Finish Options: Painted / Powder Coated / Hot Dip Galvanized

Sizes: As Per Requirment

Applications:

- Municipal plantations

- Roadside trees

- Parks & Landscapes

- Institutional and Industrial green zones

Road Barricades

Features:

- Strong, durable MS construction

- Portable, Interlocking or Fixed Frame designs

- Reflective tapes for visibility

- Branding & signage options available

Types:

- Fixed / Interlocking Barricades

- Expandable / Folding Type

- With Wheels & Custom Sign Boards

Finish Options: Painted / Galvanized

Applications: Roads, Construction Sites, Public Events, Industrial Area

Customized Fabrication

Hi-Tech Engineers specializes in tailor-made fabrication services to meet the specific needs of our clients. Whether it’s a one-off prototype or bulk production, we fabricate strictly as per client drawings, technical specifications, and timelines. Our engineering team collaborates with customers to understand the application, environmental factors, and operational loads—ensuring optimum design, durability, and performance. From material selection to surface finish, every detail is customized to ensure a perfect fit for your project.

Features:

• Fabrication as per customer drawings & technical inputs

• Custom sizes, shapes, finishes, and integration options

• Support for special materials & application-specific standards

Why Choose Hi-Tech Engineers for Fabrication?

In-house Laser Cutting & CNC Bending Machines

ISO 9001:2008 Certified Fabrication Processes

Dedicated QA/QC Team for Each Batch

Timely Delivery & Site-ready Prefab Structures

Experience with Power, Cement, Fertilizer & Refining Sectors

Fabrication based on Client Drawings, IS/ASTM Standards, and Application Needs